The automotive industry is in a constant state of evolution, driven by demands for greater fuel efficiency, stricter emissions standards, and enhanced vehicle performance. Engineers and designers are perpetually seeking innovative materials that can meet these challenges. One such material making significant inroads is expanded Polytetrafluoroethylene (ePTFE). This remarkable fluoropolymer, known for its unique properties, is becoming indispensable in various automotive applications. At SUKO, we've witnessed firsthand how ePTFE tubing is revolutionizing automotive design, offering solutions that were previously unattainable with traditional materials.

Understanding ePTFE: The Science Behind the Superiority

Before we explore its applications, let's understand what makes ePTFE so special. Standard PTFE (Polytetrafluoroethylene), commonly known by the DuPont brand name Teflon™, is prized for its low friction, chemical inertness, and high-temperature resistance. Expanded PTFE (ePTFE) takes these properties to a new level. It's created by rapidly expanding PTFE under specific conditions, resulting in a microporous structure composed of nodes interconnected by fine fibrils.

This unique structure imparts several key advantages:

- Exceptional Chemical Resistance: ePTFE is virtually inert to most chemicals, fuels, oils, and solvents found in automotive environments.

- High-Temperature Stability: It can withstand continuous operating temperatures that would degrade many other polymers. For instance, SUKO's High-Temp Expanded PTFE Pipe for Automotive Fuel/Air Systems is engineered for operation at 260°C.

- Low Permeation: The dense, yet microporous, structure significantly reduces the permeation of gases and liquids, a critical factor for emissions control.

- Hydrophobicity: ePTFE repels water and oils, preventing absorption and maintaining performance in moist or oily conditions.

- Flexibility and Durability: Despite its strength, ePTFE can be made into flexible tubing that withstands vibration and repeated flexing, contributing to ePTFE durability automotive applications.

- Lightweight: It's inherently a lightweight automotive component, contributing to overall vehicle weight reduction and improved fuel economy.

Compared to traditional materials like rubber or standard plastics, ePTFE offers a superior combination of these properties, making it an ideal candidate for critical automotive systems.

Boosting Automotive Performance with ePTFE Tubing

The quest for enhanced performance – be it power, responsiveness, or efficiency – is a cornerstone of automotive engineering. ePTFE tubing plays a vital role in several areas:

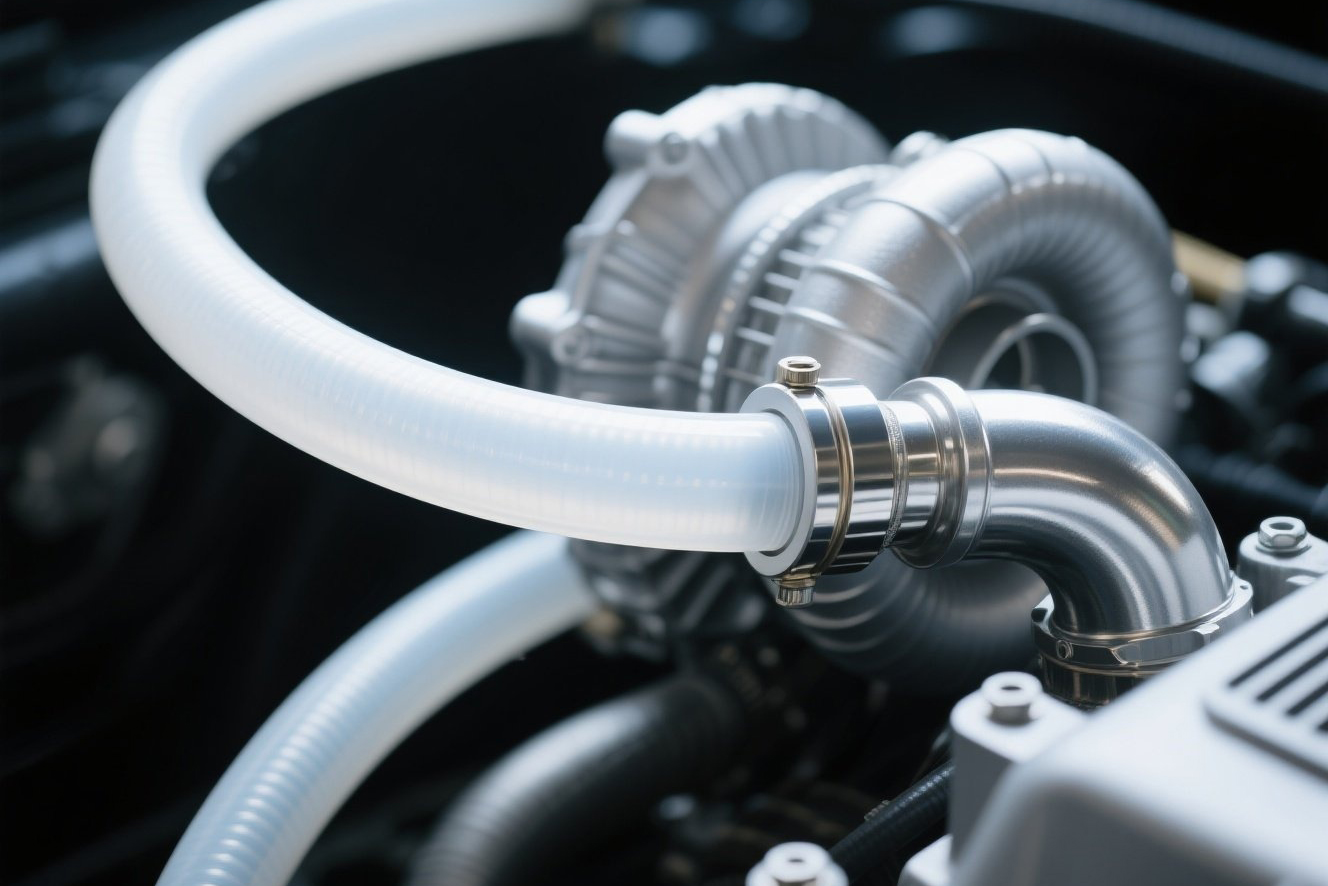

1. Turbocharger Systems: Handling the Heat and Pressure

Turbochargers significantly increase engine power and efficiency by forcing more air into the combustion chambers. However, they operate under extreme conditions, generating high temperatures and pressures.

- The Challenge: Traditional hoses can degrade, crack, or swell under such duress, leading to boost leaks, reduced performance, and potential engine damage.

- The ePTFE Solution: A turbocharger ePTFE hose excels in this environment. Its high-temperature resistance ensures integrity even close to the turbocharger unit. Its smooth inner surface minimizes airflow restriction, allowing for quicker spool-up and improved throttle response. Furthermore, its robustness prevents kinking or collapsing under vacuum or pressure, ensuring consistent performance. SUKO's ePTFE solutions are designed to maintain their structural integrity and performance under these demanding turbocharger conditions.

2. Fuel Systems: Optimizing Delivery and Efficiency

Efficient and reliable fuel delivery is paramount for engine performance and economy.

- The Challenge: Modern fuels, especially those with aggressive additives or alternative compositions like CNG (Compressed Natural Gas), can degrade conventional fuel lines. Permeation of fuel vapors through hose walls leads to fuel loss and emissions. Vapor lock, where fuel vaporizes in the lines due to heat, can starve the engine of fuel.

- The ePTFE Solution: ePTFE tubing, like SUKO's High-Temp Expanded PTFE Pipe, offers exceptional chemical resistance to a wide range of fuels. A key benefit is its dramatically reduced hydrocarbon permeation – up to 90% less compared to traditional rubber hoses. This not only helps with emissions (more on that later) but also improves overall ePTFE automotive efficiency by ensuring all the fuel reaches the engine. Its ability to withstand direct fuel exposure while preventing vapor lock, even at high temperatures, makes it essential for applications like CNG vehicle fuel rails and high-performance fuel injection systems.

3. Lightweighting for Agility and Economy

Every gram saved in a vehicle contributes to better performance, handling, and fuel economy.

- The Challenge: Traditional components, often made from metal or dense rubbers, add unnecessary weight.

- The ePTFE Solution: ePTFE is inherently a lightweight automotive component. Replacing heavier hoses and tubes with ePTFE alternatives can contribute to significant weight savings, especially when considering the cumulative effect across multiple systems. This reduction in mass improves acceleration, braking, and handling dynamics, while also directly contributing to lower fuel consumption and emissions.

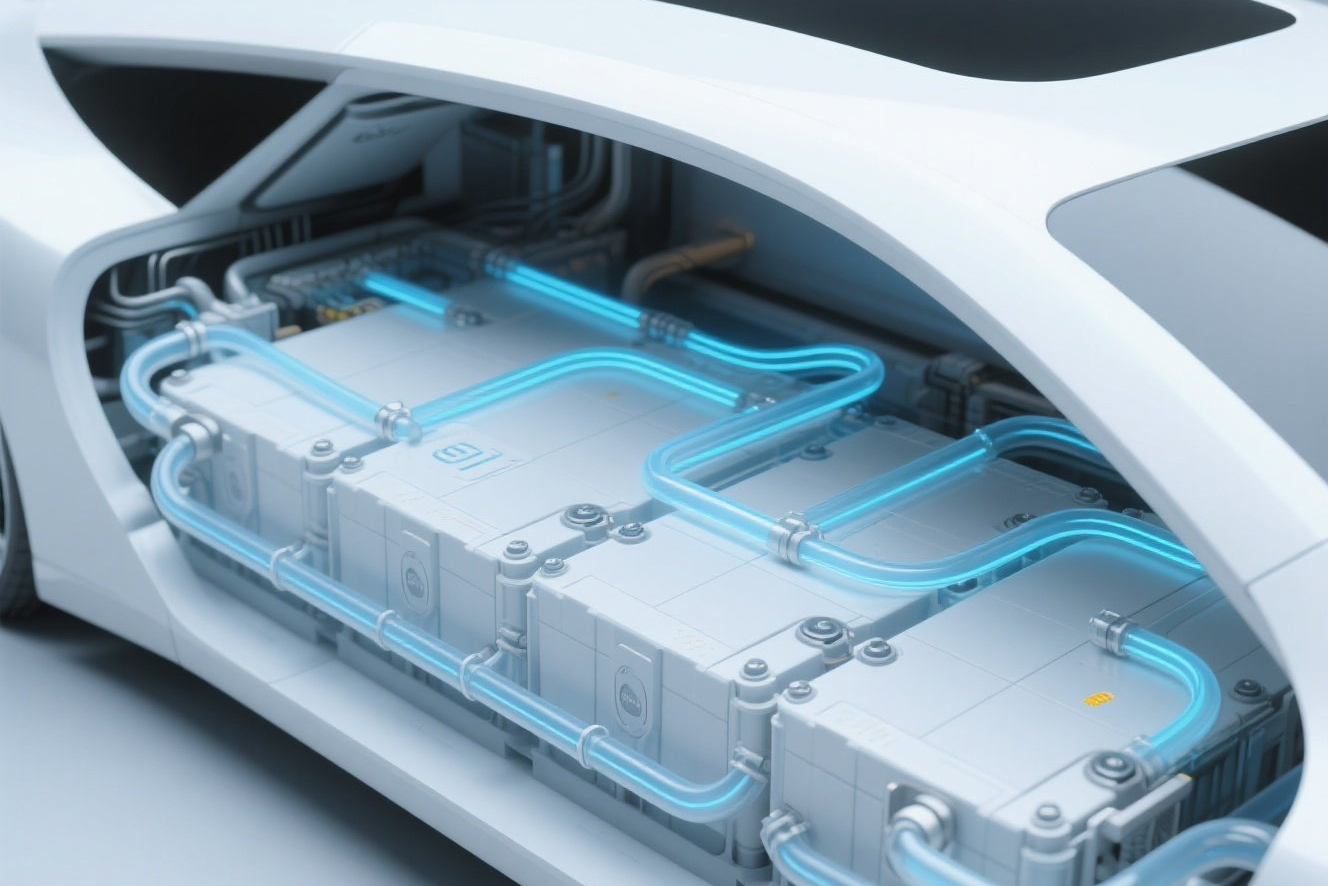

4. Advanced Fluid Management: EV Battery Cooling and More

The rise of Electric Vehicles (EVs) brings new challenges, particularly in thermal management for batteries.

- The Challenge: EV batteries generate significant heat during charging and discharging. Effective cooling is crucial for performance, longevity, and safety. Cooling lines must be chemically compatible with dielectric coolants, electrically non-conductive, and durable.

- The ePTFE Solution: ePTFE tubing is an excellent choice for EV battery cooling lines. Its dielectric properties prevent electrical issues, while its chemical inertness ensures compatibility with advanced coolants. Its durability and temperature resistance ensure reliable long-term performance in these critical systems. SUKO's ePTFE products are increasingly finding applications in these next-generation thermal management systems.

ePTFE Tubing: A Critical Component for Emissions Control

Meeting increasingly stringent global emissions standards is a primary driver of automotive innovation. ePTFE tubing offers tangible benefits in reducing harmful emissions.

1. Drastically Reducing Hydrocarbon Permeation

Volatile Organic Compounds (VOCs), primarily unburnt hydrocarbons (HC), are a major component of smog and a regulated pollutant. A significant source of HC emissions in vehicles is permeation through fuel lines and vapor hoses.

- The Challenge: Traditional rubber hoses are relatively permeable to fuel vapors. Over time, these vapors escape into the atmosphere, contributing to evaporative emissions.

- The ePTFE Solution: As mentioned, ePTFE's microporous structure makes it an excellent barrier material. SUKO’s High-Temp Expanded PTFE Pipe can reduce hydrocarbon permeation by as much as 90% compared to conventional rubber hoses. This makes emissions control tubing made from ePTFE a key technology for meeting PZEV (Partial Zero Emission Vehicle) and ZEV (Zero Emission Vehicle) mandates. By minimizing these fugitive emissions, ePTFE directly contributes to cleaner air.

According to studies by regulatory bodies like the U.S. Environmental Protection Agency (EPA) and the California Air Resources Board (CARB), evaporative emissions from fuel systems can account for a substantial portion of a vehicle's total hydrocarbon emissions. Utilizing low-permeation materials like ePTFE is a recognized strategy to combat this.

2. Enhancing System Durability and Preventing Leaks

Degradation of components in the fuel and emissions systems can lead to leaks, which not only release pollutants but also impair engine performance and efficiency.

- The Challenge: Hoses exposed to heat, chemicals, and vibrations can crack, harden, or become brittle over time, leading to leaks.

- The ePTFE Solution: The inherent ePTFE durability automotive applications demand is a major asset. Its resistance to chemical attack, temperature extremes, and mechanical stress means ePTFE tubing maintains its integrity for longer periods. This longevity reduces the likelihood of leaks developing, ensuring that fuel and vapors are contained within the system as designed, thereby maintaining optimal emissions control performance throughout the vehicle's lifespan.

3. Supporting Efficient Combustion

While not a direct combustion component, ePTFE contributes indirectly by ensuring other systems operate at peak efficiency.

- The Challenge: Inconsistent fuel delivery or air leaks in intake systems (like turbocharger plumbing) can lead to suboptimal combustion, resulting in increased emissions of CO, NOx, and unburnt hydrocarbons.

- The ePTFE Solution: By providing reliable, leak-free conduits for fuel and air (especially in turbocharger ePTFE hose applications), ePTFE ensures the engine receives the precise fuel-air mixture required for efficient and clean combustion. This optimized combustion process minimizes the production of harmful exhaust pollutants.

Key Advantages of ePTFE Tubing in Automotive Applications: A Summary

To provide a clearer overview, here's a table summarizing the key advantages:

| Feature of ePTFE | Benefit for Automotive Systems | Impact on Performance & Emissions |

|---|---|---|

| High-Temperature Resistance | Maintains integrity in hot engine bays, near exhaust/turbo | Prevents component failure, ensures consistent system operation |

| Exceptional Chemical Inertness | Resists degradation from fuels, oils, coolants, additives | Long service life, prevents leaks, compatible with various fluids |

| Low Permeation | Significantly reduces escape of fuel vapors | Drastically cuts evaporative emissions (HC), improves fuel economy |

| Lightweight | Reduces overall vehicle mass | Enhances fuel efficiency, improves handling and acceleration |

| Flexibility & Durability | Withstands vibration, flexing; resists kinking | Reliable performance in dynamic environments, long component life |

| Smooth Inner Surface | Minimizes flow restriction for fluids and gases | Improves turbocharger response, efficient fluid transfer |

| Hydrophobicity | Repels water and oil | Maintains performance in harsh under-hood conditions |

| Dielectric Properties | Electrically non-conductive | Safe for use in EV battery cooling and other electrical systems |

SUKO: Your Partner for Advanced ePTFE Automotive Solutions

At SUKO (https://www.sukoptfe.com/), we specialize in harnessing the power of PTFE and ePTFE for demanding industrial applications, including the automotive sector. Our High-Temp Expanded PTFE Pipe for Automotive Fuel/Air Systems is a testament to our commitment to innovation and quality.

Why choose SUKO's ePTFE solutions?

- Expertise: With years of experience in fluoropolymer processing, we understand the nuances of material science and application engineering.

- Quality: Our products are manufactured to stringent quality standards, ensuring reliability and consistent performance. Our ePTFE pipes are engineered for operation at 260°C and can reduce hydrocarbon permeation by 90% compared to rubber hoses.

- Customization: We can work with you to develop tailored solutions that meet your specific automotive requirements.

- Proven Applications: Our ePTFE tubing is ideal for:

- EV battery cooling lines

- Turbocharged air ducts (as a turbocharger ePTFE hose)

- CNG vehicle fuel rails

- Fuel vapor return lines (as emissions control tubing)

- Other critical fluid and air transfer systems demanding ePTFE durability automotive grade and lightweight automotive components.

The Road Ahead: The Expanding Role of ePTFE

As automotive technology continues to advance towards greater efficiency, electrification, and stringent environmental targets, the role of advanced materials like ePTFE will only grow. Its unique combination of properties makes it an enabling technology, allowing engineers to design systems that are lighter, more durable, more efficient, and cleaner.

From internal combustion engines pushing the boundaries of performance to the sophisticated thermal management systems of electric vehicles, ePTFE tubing is proving to be an indispensable component.

Take the Next Step Towards Enhanced Automotive Solutions

The benefits of incorporating ePTFE tubing into automotive designs are clear: enhanced performance, improved fuel efficiency, significant reductions in emissions, and superior durability. If you're looking to leverage these advantages for your automotive applications, SUKO is here to help.

- ATTENTION: Are you facing challenges with material limitations in your automotive systems?

- INTEREST: Imagine components that withstand extreme temperatures, resist aggressive chemicals, drastically cut emissions, and contribute to lighter, more efficient vehicles. SUKO's ePTFE solutions offer precisely this.

- DESIRE: Elevate your automotive designs with our High-Temp Expanded PTFE Pipe, engineered for superior performance and environmental responsibility. Picture the enhanced reliability and efficiency your systems could achieve.

- ACTION: Don't let outdated materials hold back your innovation.

- Contact SUKO today to discuss your specific needs: https://www.sukoptfe.com/contact/

- Request a quote for our advanced ePTFE tubing solutions.

- Learn more about our comprehensive range of PTFE and ePTFE products by visiting our website: https://www.sukoptfe.com/

- For direct inquiries, email us at: info@sukoptfe.com

Partner with SUKO and drive the future of automotive performance and sustainability.

Frequently Asked Questions (FAQ)

Q1: What makes ePTFE tubing superior to traditional rubber hoses in automotive fuel systems?

A1: ePTFE tubing offers significantly lower fuel permeation (up to 90% less than rubber), superior chemical resistance to aggressive fuels and additives, and higher temperature tolerance. This means SUKO's ePTFE tubes, like our High-Temp Expanded PTFE Pipe, help reduce evaporative emissions, prevent vapor lock, ensure ePTFE automotive efficiency, and offer greater ePTFE durability automotive applications require, leading to a longer service life.

Q2: How does ePTFE tubing contribute to meeting stricter emissions standards?

A2: Its primary contribution is through drastically reducing hydrocarbon permeation from fuel lines and vapor recovery systems. This directly lowers a vehicle's evaporative emissions, a key factor in meeting regulations like PZEV and ZEV. Furthermore, its durability prevents leaks that could release pollutants. SUKO's emissions control tubing made from ePTFE is specifically designed for this purpose.

Q3: Can SUKO's ePTFE tubing be used in electric vehicle (EV) applications?

A3: Absolutely. ePTFE tubing is an excellent material for EV battery cooling lines. Its key advantages include high-temperature resistance, chemical compatibility with dielectric coolants, excellent dielectric properties (electrical insulation), and being a lightweight automotive component. SUKO offers ePTFE solutions suitable for these demanding EV thermal management systems. You can learn more by visiting https://www.sukoptfe.com/ or contacting us.

Post time: Jun-17-2025